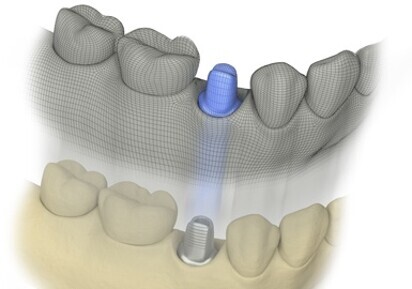

Available for all major implants systems, Atlantis™ remains a market-leading CAD/CAM abutment solution in North America, with steadily increasing numbers of dental laboratories and dentists choosing Atlantis abutments for their patient-specific, dental implant restorative needs, the company said.

“The continued growth of Atlantis is, in part, due to our commitment to listening and responding to the feedback and needs of our customers,” says Craig Rodriguez, vice president of marketing, Astra Tech Inc. (North America). “We go through a rigorous development process that ensures innovation without compromise to reliability and predictable results. These solutions all positively contribute to our customers’ process efficiency and profitability.”

Atlantis lab-based scanning and Atlantis Abutment core file are examples of services that leverage technology for a more efficient workflow. A steady stream of new product and service options will be introduced throughout 2012, further reinforcing Astra Tech Dental’s position within the area of digital dentistry.

Atlantis scanning for 3Shape

First announced in 2011, Astra Tech’s strategic alliance with 3Shape A/S, the Danish-based provider of 3-D scanners and CAD/CAM software solutions, continues with the development of Atlantis lab-based scanning for 3Shape scanners. Atlantis lab-based scanning allows for the dental models to be kept at the laboratory and provides advantages for the dental laboratory such as reduced time to delivery and reduced cost in handling and transportation.

The software interface enabling the 3Shape dental scanners to communicate with the Atlantis VAD™ (Virtual Abutment Design) software is now in the pre-market test phase.

One of the first participants of the pre-market testing is Chris May, owner of May Dental Arts (Fenton, Mo.).

“The overall experience using the 3Shape scanner to send files to Astra Tech for the production of Atlantis abutments has been great,” May said. “This digital workflow has helped my laboratory to shave off almost two days of our production time. And because our laboratory often restores cases with multiple disciplines (veneers/crowns and implant combinations), lab-based scanning allows us the flexibility to continue working on these cases while the abutments are being milled.

“Not having to physically send out our case models makes the overall process feel even more integrated. In fact, it feels as if Atlantis production is located right in our own laboratory,” he added.

Atlantis Abutment Core File

Astra Tech will offer Atlantis Abutment Core File to users of the design software 3Shape DentalDesigner. Atlantis Abutment Core File is a high-precision digital file of an Atlantis abutment that represents the outer surface of the manufactured Atlantis abutment and includes all corresponding scanned data. The Atlantis Abutment Core File can be used for designing a coping in the 3Shape Dental Designer software before receipt of the final abutment, thus replacing the need to scan the abutment. The service contributes to a shorter turnaround time for the production of the final restoration.

Atlantis and Atlantis VAD are trademarks of Astra Tech. All other trademarks are the property of their respective owners.

Atlantis patient-specific abutments

Atlantis patient-specific abutments are designed and fabricated using Atlantis VAD (Virtual Abutment Design) software, a patented process that combines state-of-the-art 3-D optical scanning, advanced software and manufacturing methods to deliver patient-specific abutments that eliminates the need for hand modification.

Atlantis patient-specific abutments are available for all major implant systems and in biocompatible materials such as titanium, gold-shaded titanium and different shades of zirconia, including a translucent zirconia in white for the Atlantis Crown Abutment.

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

International / International

International / International

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East