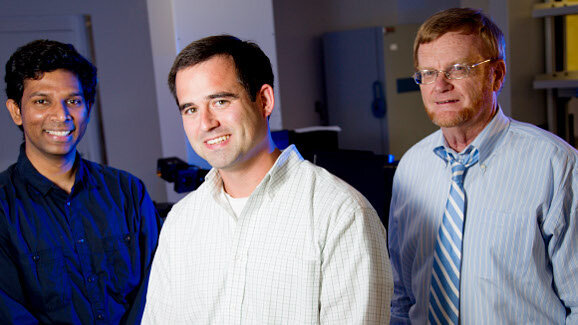

ATHENS, Ga., USA: A University of Georgia researcher has invented a new technology that renders medical linens and clothing, face masks, paper towels and diapers permanently germ free. The simple and inexpensive antimicrobial technology works on natural and synthetic materials and can be applied during the manufacturing process or at home.

“The spread of pathogens on textiles and plastics is a growing concern, especially in healthcare facilities and hotels, which are ideal environments for the proliferation and spread of very harmful microorganisms, but also in the home,” said Jason Locklin, the inventor of the new technology and Assistant Professor of Chemistry in the Franklin College of Arts and Sciences, as well as in the Faculty of Engineering.

According to Locklin, the new antimicrobial technology was tested on many of the pathogens common in healthcare settings, including staph., strep., E. coli, pseudomonas and acinetobacter. After just a single application, no bacterial growth was observed on the textile samples added to the culture—even after 24 hours at 99 F (37 C).

Moreover, in testing, the treatment remained fully active after multiple hot water laundry cycles, demonstrating that the antibacterial substance does not leach out from the textiles even under harsh conditions. “Leaching could hinder the applicability of this technology in certain industrial segments, such as food packaging, toys, I.V. bags and tubing, for example,” said Gennaro Gama, University of Georgia Research Foundation (UGARF) senior technology manager.

The antimicrobial treatment, which is available for licensing from the UGARF, effectively kills a wide spectrum of bacteria, yeasts and molds that can cause disease, break down fabrics, create stains, and produce odors.

According to the Centers for Disease Control and Prevention, approximately one of every 20 hospitalized patients will contract a healthcare-associated infection. Lab coats, scrub suits, uniforms, gowns, gloves and linens are known to harbor the microbes that cause patient infections.

Consumers’ concern about harmful microbes has driven the market for clothing, undergarments, footwear and home textiles with antimicrobial properties. But to be practical, both commercial and consumer antimicrobial products must be inexpensive and lasting.

“Similar technologies are limited by cost of materials, use of noxious chemicals in the application or loss of effectiveness after a few washings,” said Gama. “Locklin’s technology uses ingeniously simple, inexpensive and scalable chemistry.”

Gama said the technology is simple to apply in the manufacturing of fibers, fabrics, filters and plastics. It also can bestow antimicrobial properties on finished products, such as athletic wear and shoes, and textiles for the bedroom, bathroom and kitchen.

“The advantage of UGARF’s technology over competing methods,” said Gama, “is that the permanent antimicrobial can be applied to a product at any point of the manufacture-sale-use continuum. In contrast, competing technologies require blending of the antimicrobial in the manufacturing process.”

“In addition,” said Gama, “If for some reason the antimicrobial layer is removed from an article—through abrasion, for example—it can be reapplied by simple spraying.”

Other markets for the antimicrobial technology include medical and dental instrumentation, military apparel and gear, food packaging, plastic furniture, pool toys, bandages and plastic items.

Thin films of the new substance also can be used to change other surface properties of both cellulose- and polymer-based materials. “It can change a material’s optical properties—color, reflectance, absorbance and iridescence—and make it repel liquids, all without changing other properties of the material,” said Gama.

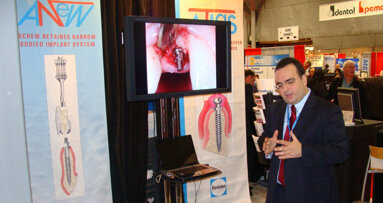

Many companies have products that can dramatically improve a patient’s life and overall wellbeing. One such company is Dentatus, whose innovative ...

AMD Lasers has launched the Learn Lasers Academy, a new digital education platform offering free continuing education (CE) programmes for dental ...

NEW YORK, NY, USA: Tyler covered his mouth when he smiled, barely spoke and refrained from eating in public whenever possible. Although he was in desperate ...

NEW YORK, N.Y., USA: There’s always plenty of excitement in New York City. From Friday, Nov. 26, to Wednesday, Dec. 1, that excitement will extend to the ...

Dr. Lee Ann Brady is a nationally recognized dentist and dental educator who says her goal is to partner with patients to assist them in making the best ...

Revo-S developed by MICRO-MEGA, with only three nickel-titanium files, simplifies the initial endodontic treatment and optimizes the cleaning action. The ...

Beutlich Pharmaceuticals has added to its family of HurriCaine products.

NEW YORK, N.Y., USA: TotalCare, an industry leader in dental infection prevention, has announced a new corporate brand identity, which the company says ...

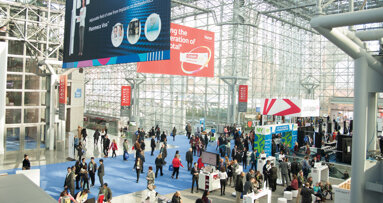

NEW YORK, N.Y., USA: Registration is now open for the 2013 Greater New York Dental Meeting (GNYDM). Organizers of the 89th annual meeting anticipate the ...

Tens of thousands of dental professionals gathered in Manhattan the weekend after Thanksgiving for the Greater New York Dental Meeting (GNYDM). It was an ...

Live webinar

Tue. 24 February 2026

1:00 PM EST (New York)

Prof. Dr. Markus B. Hürzeler

Live webinar

Tue. 24 February 2026

3:00 PM EST (New York)

Prof. Dr. Marcel A. Wainwright DDS, PhD

Live webinar

Wed. 25 February 2026

11:00 AM EST (New York)

Prof. Dr. Daniel Edelhoff

Live webinar

Wed. 25 February 2026

1:00 PM EST (New York)

Live webinar

Wed. 25 February 2026

8:00 PM EST (New York)

Live webinar

Tue. 3 March 2026

11:00 AM EST (New York)

Dr. Omar Lugo Cirujano Maxilofacial

Live webinar

Tue. 3 March 2026

8:00 PM EST (New York)

Dr. Vasiliki Maseli DDS, MS, EdM

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

International / International

International / International

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register