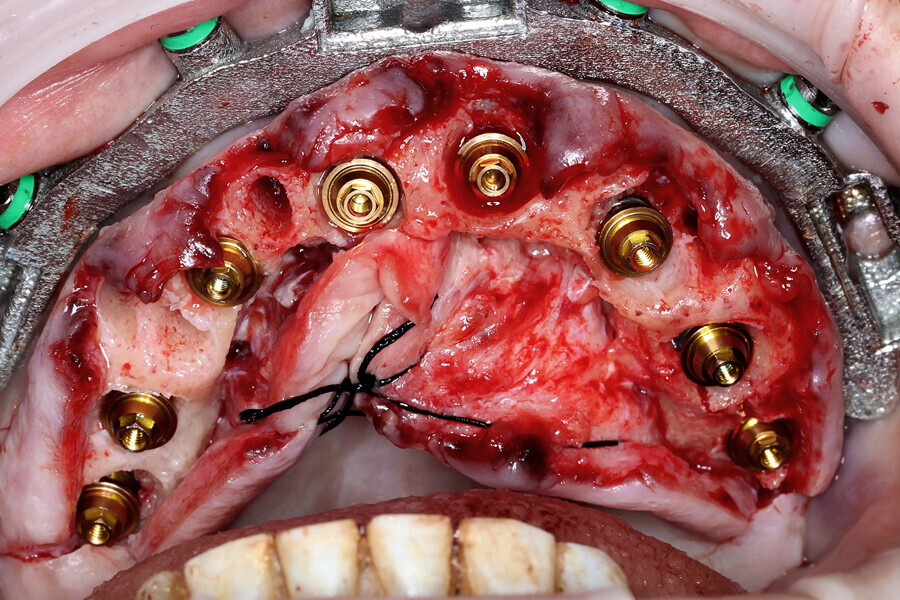

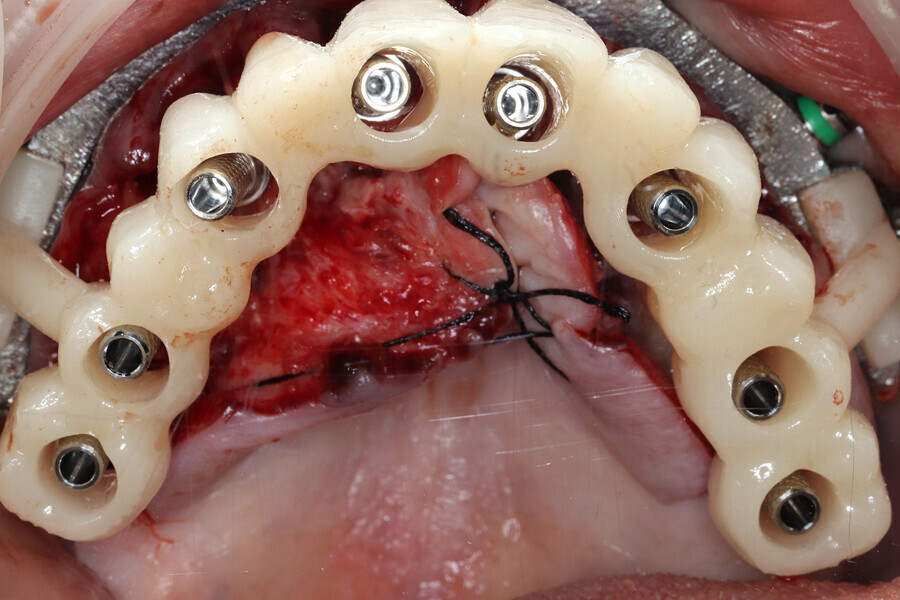

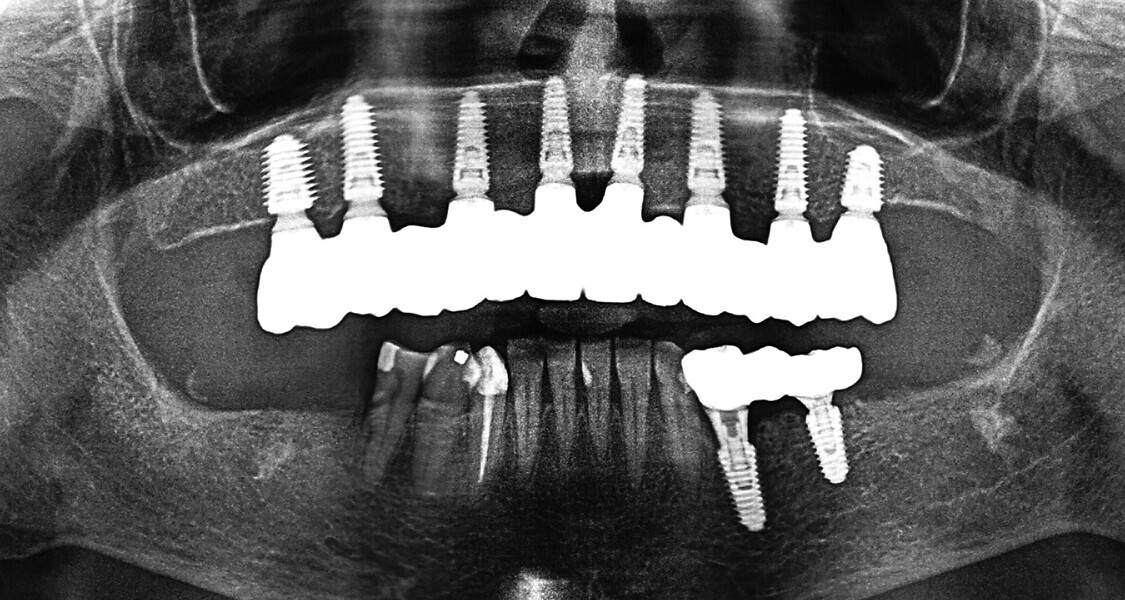

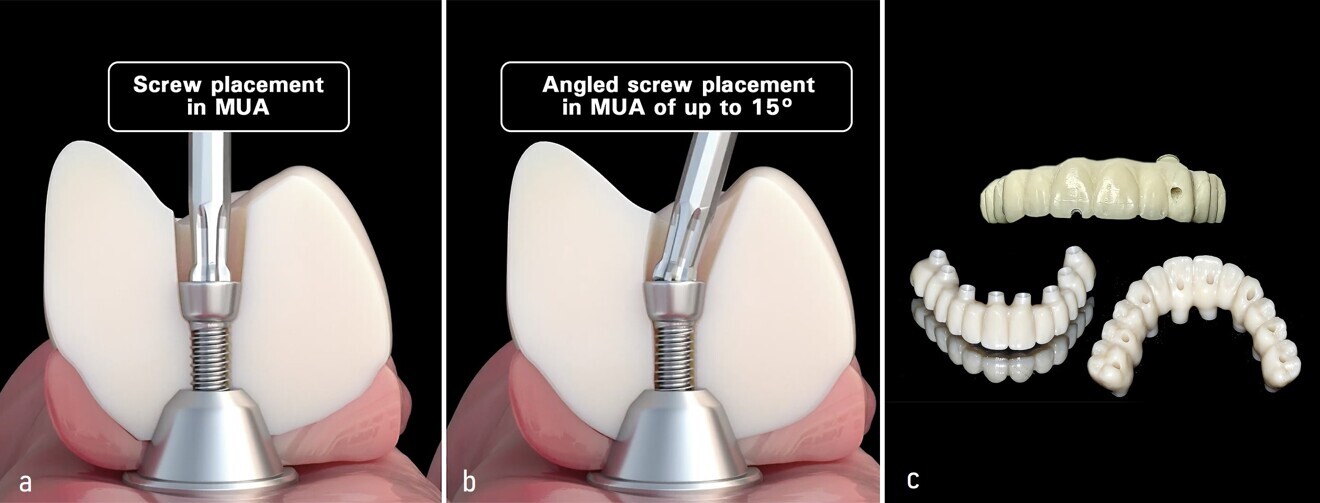

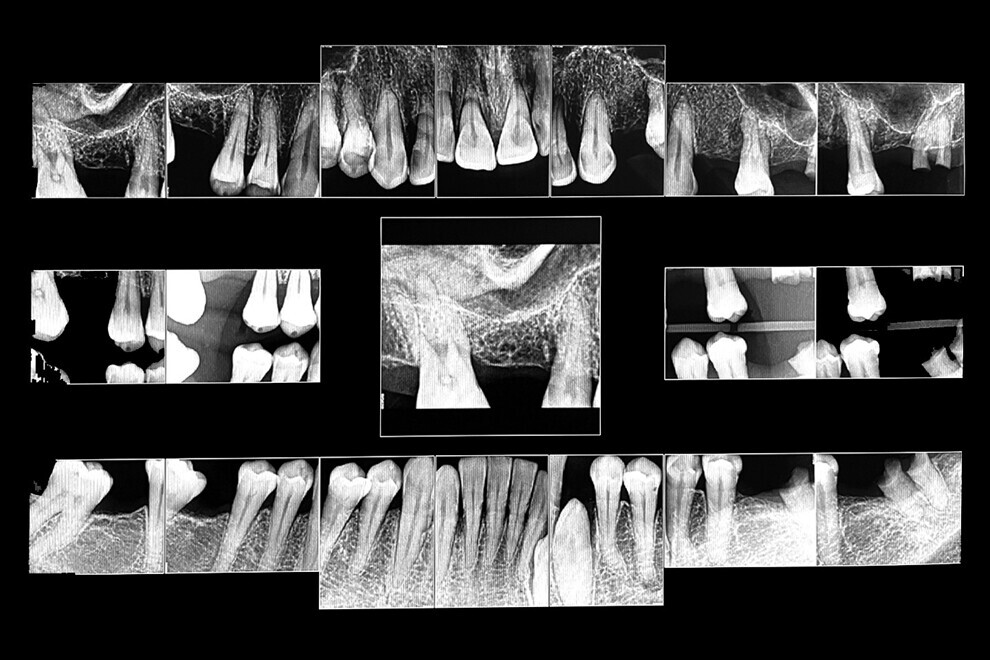

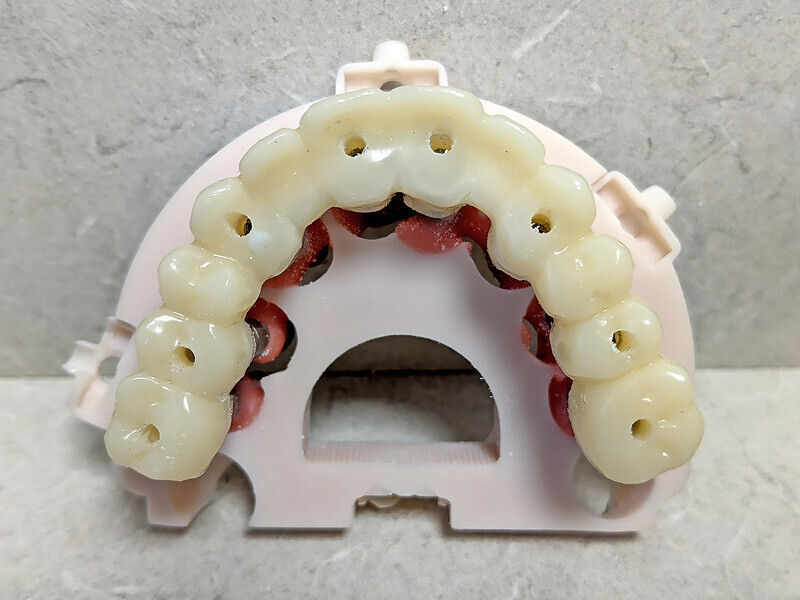

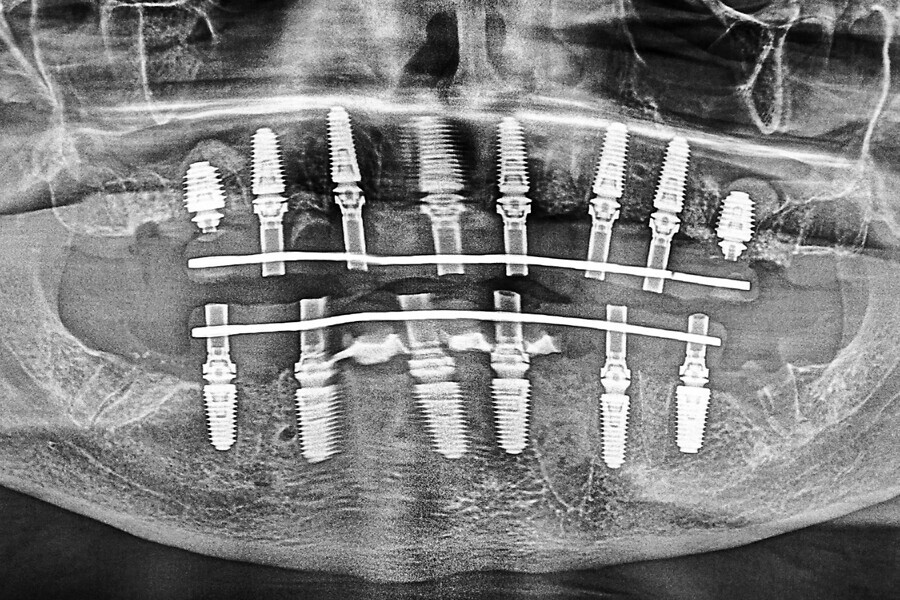

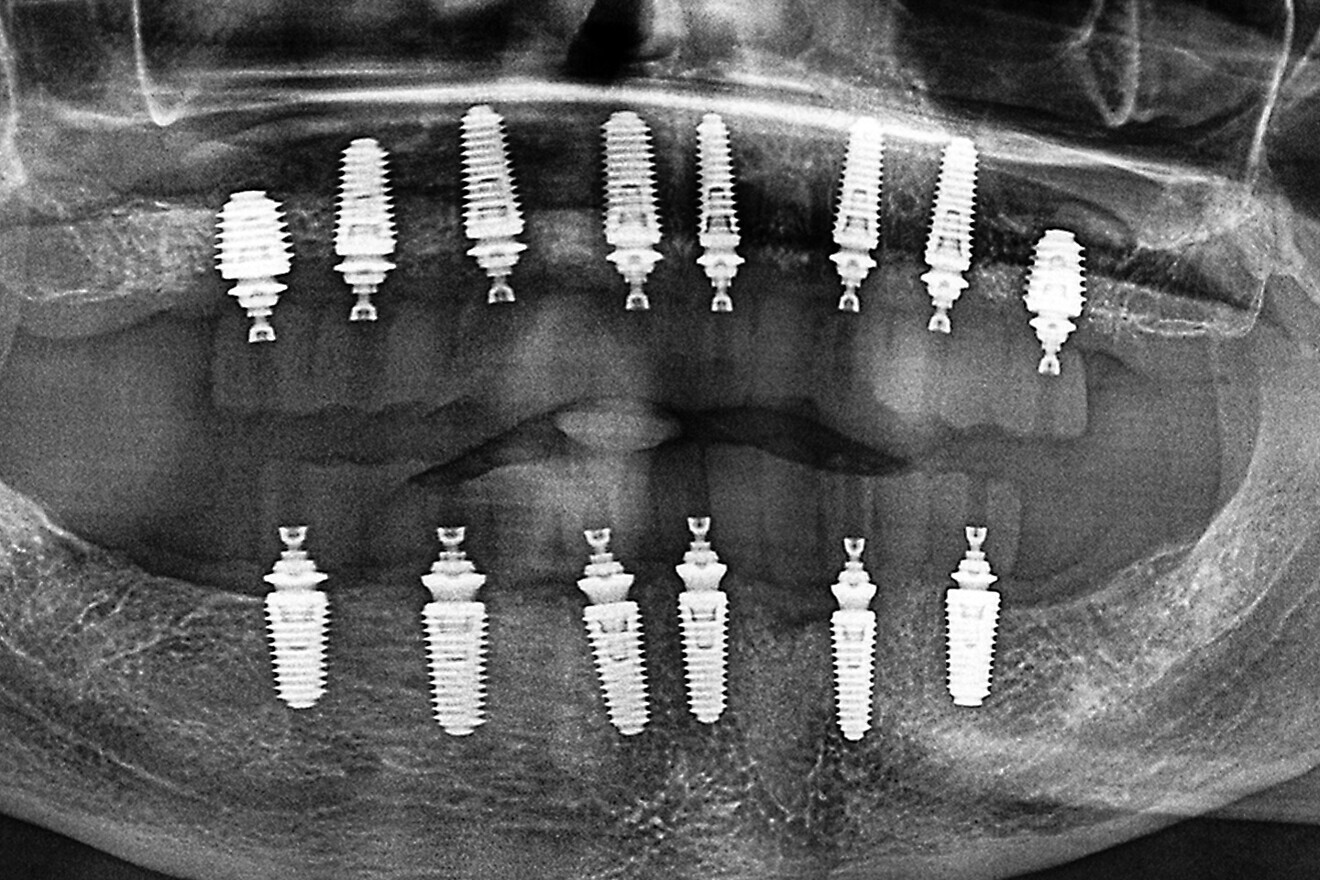

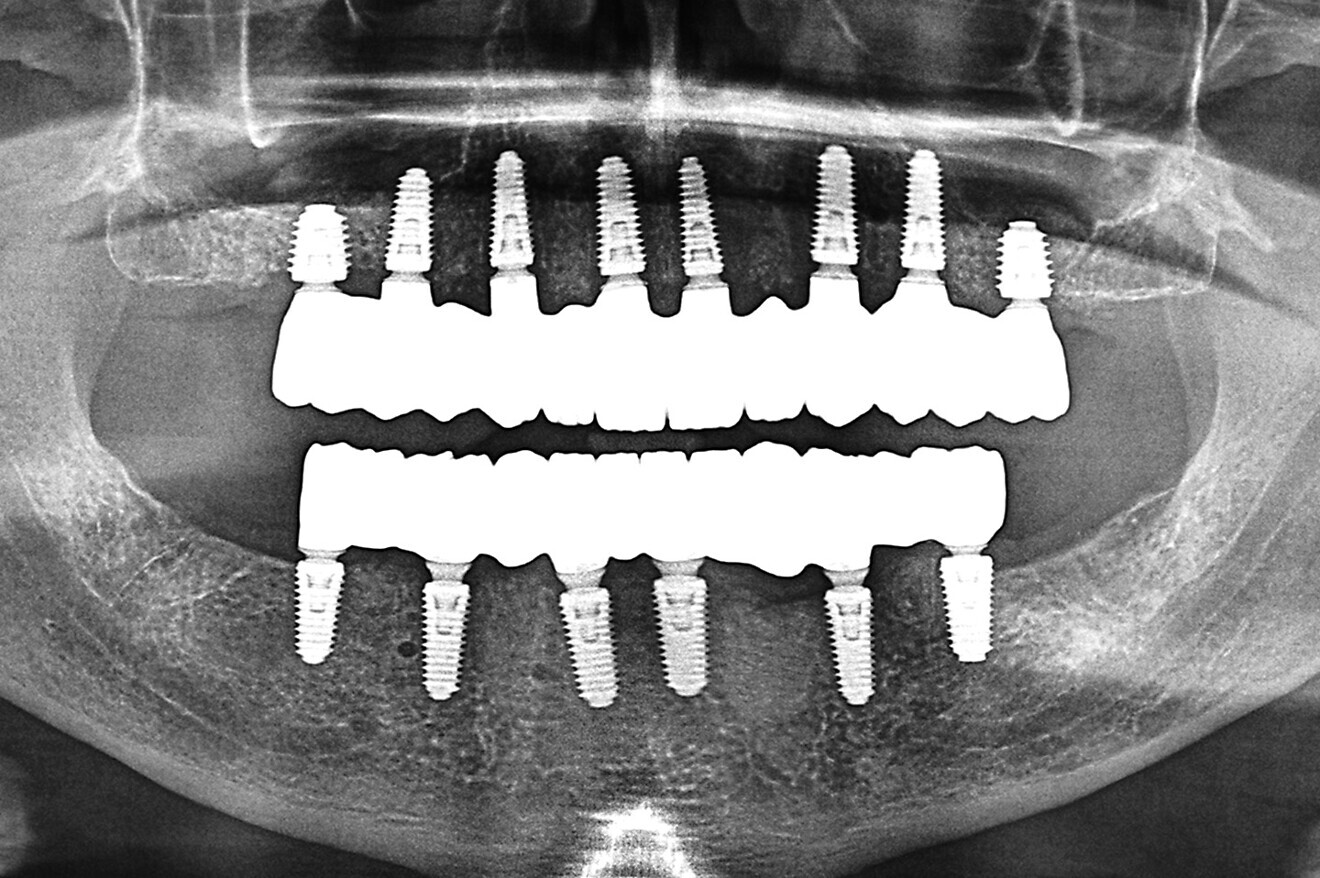

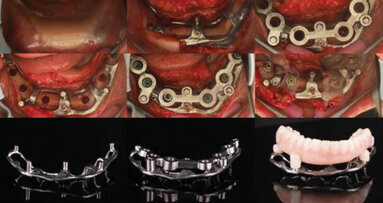

The final restorations were passively and accurately seated ten days later uneventfully using Vortex LA VIS screws. Confirmation records were taken with photographs, radiographs and digital articulation to recheck fit, function, phonetics and occlusion (Fig. 17a). The patient was extremely satisfied with his final restorations, describing the process as life-changing and surprisingly fast in comparison with what he had heard about full-mouth implant therapy. He was especially pleased with the speed at which the final process was able to be completed (Figs. 17b & c).

Conclusion

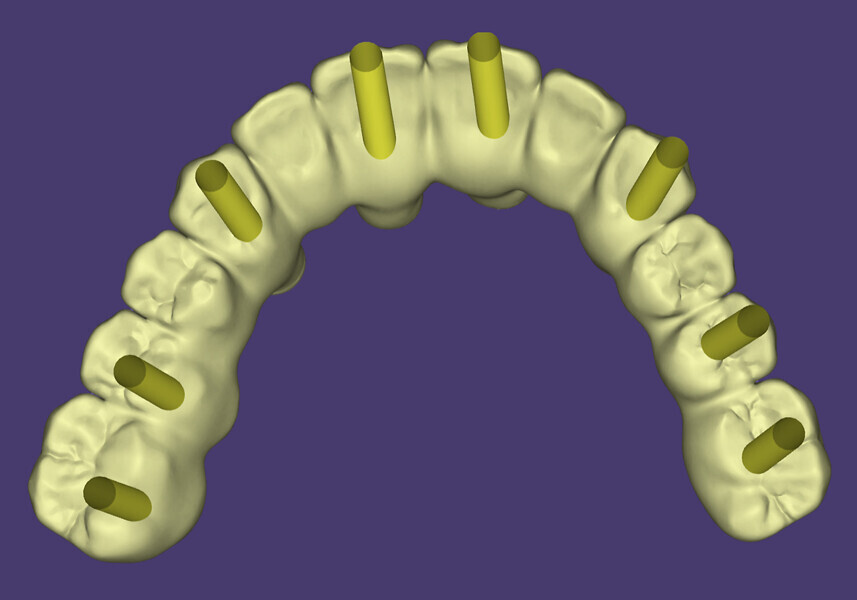

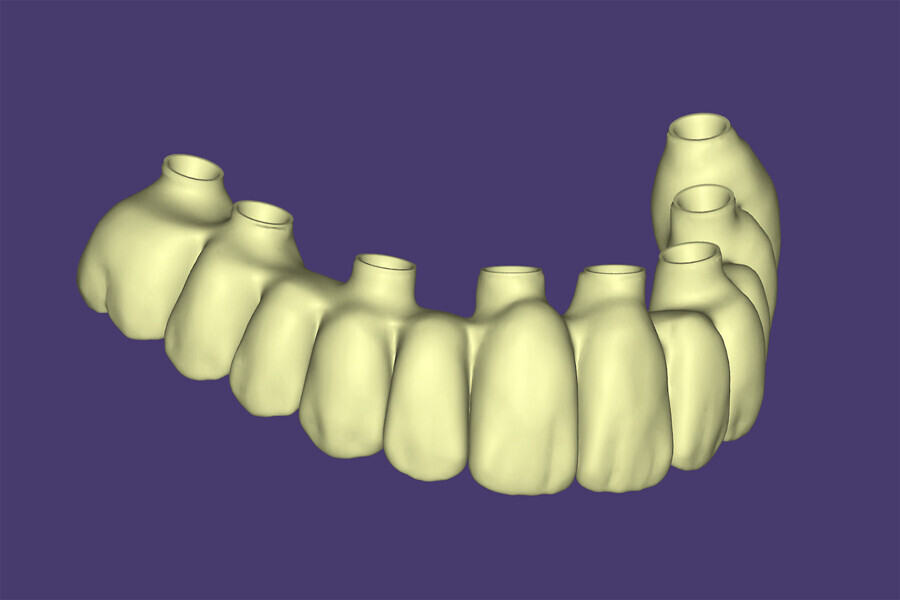

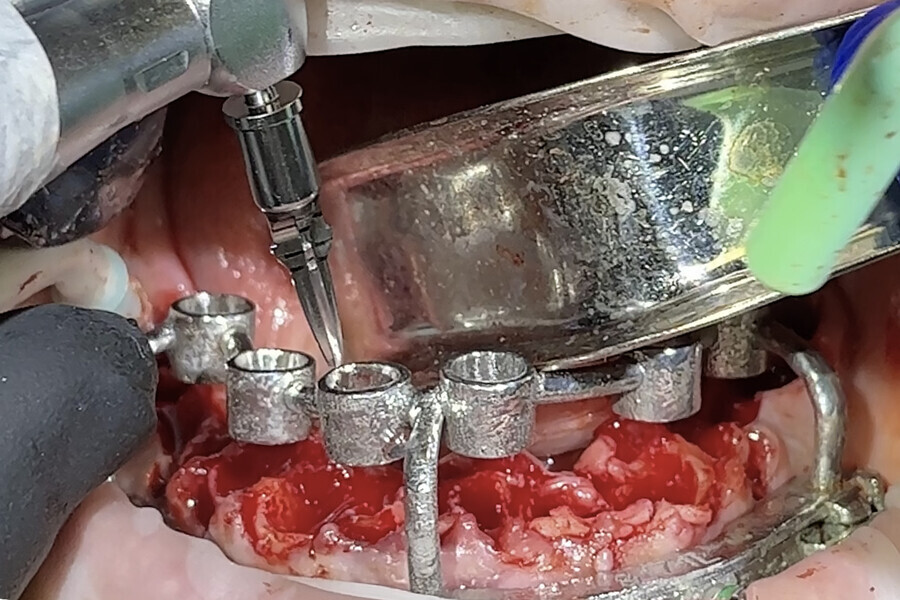

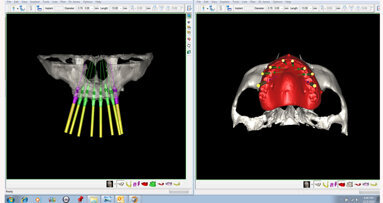

With proper diagnosis and treatment planning, single-arch or full-mouth implant reconstruction can be completed in a timely manner under ideal circumstances. The implementation of restoratively driven guided surgery can improve accuracy and ensure proper implant placement, including depth and angulation. Data collection at either the time of surgery or postoperatively can improve the accuracy and speed at which finalisation can be completed.

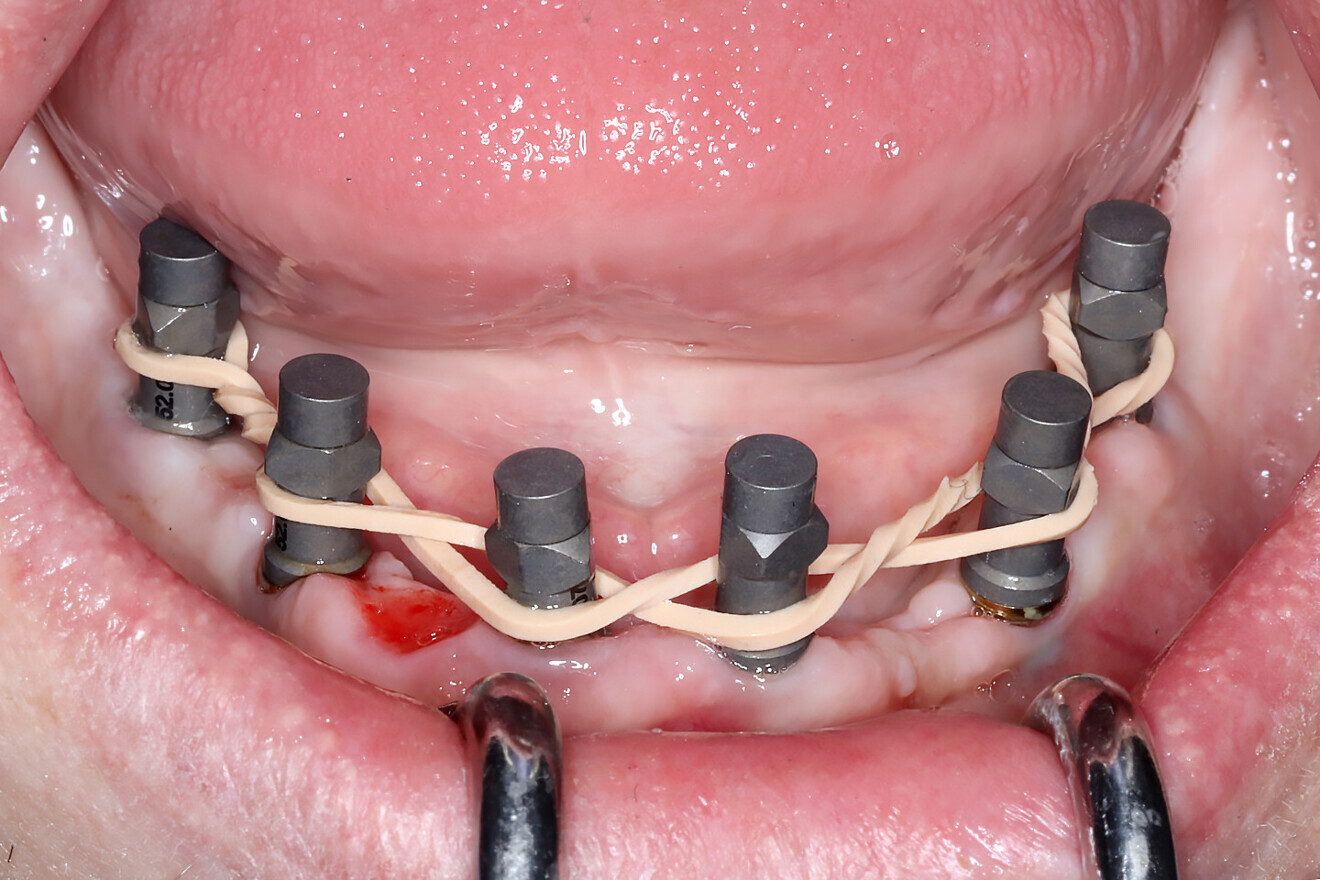

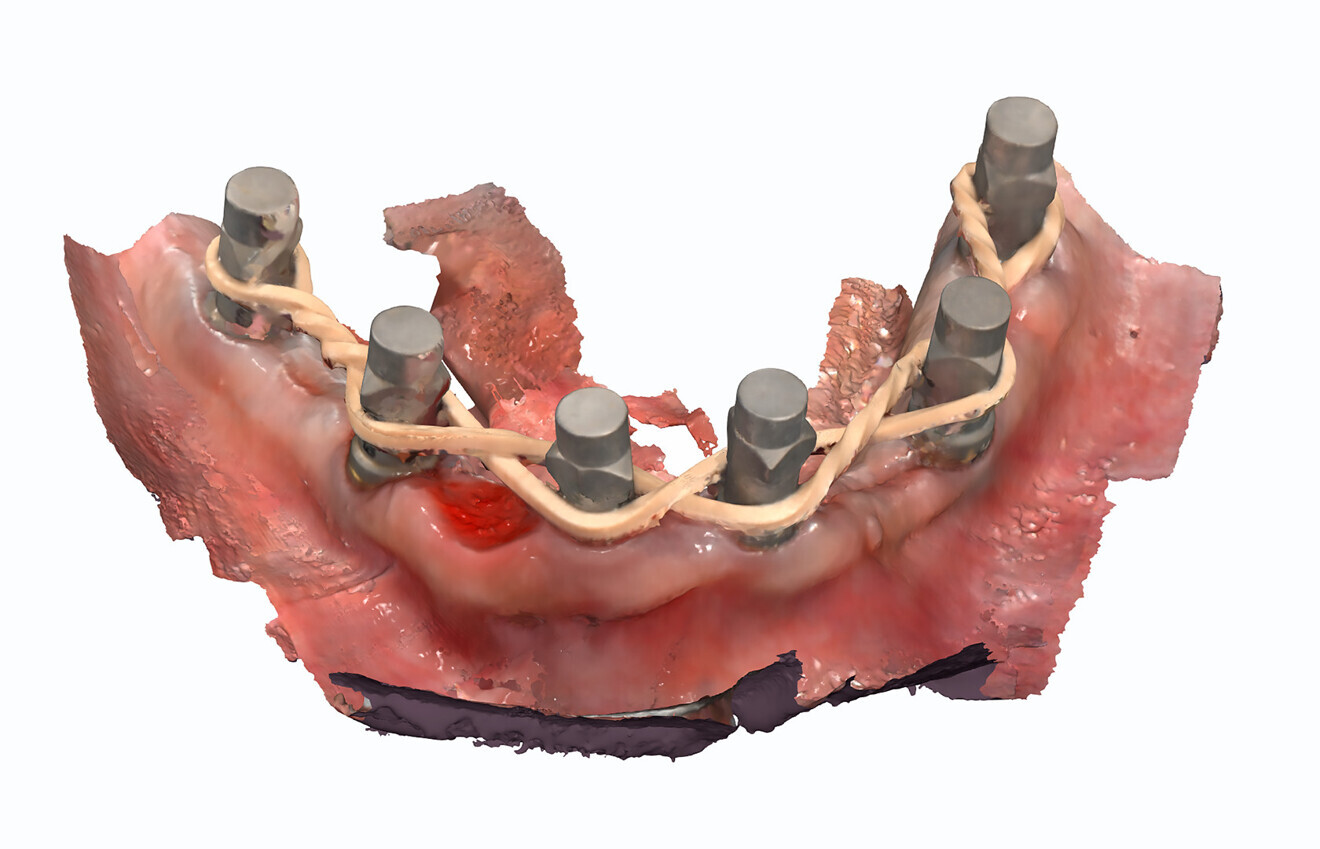

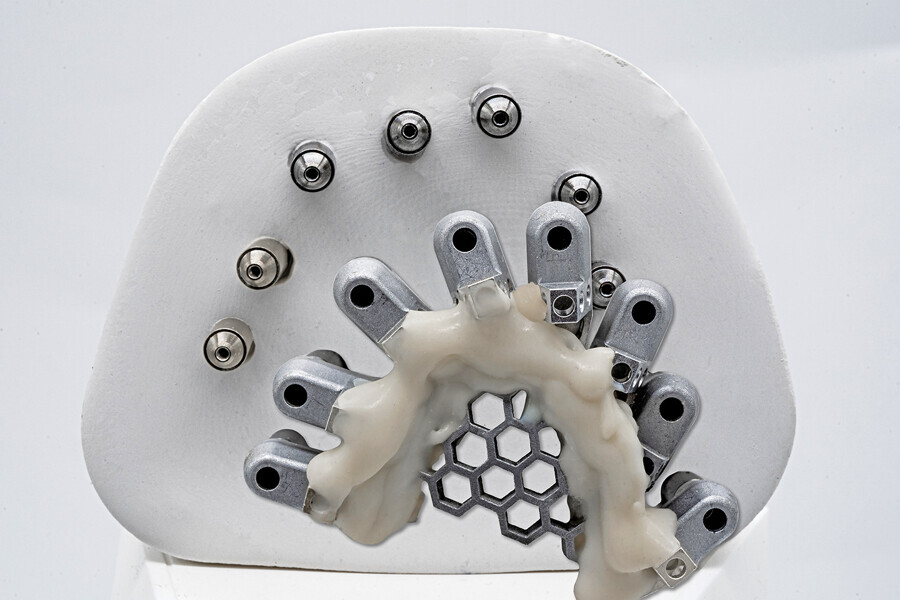

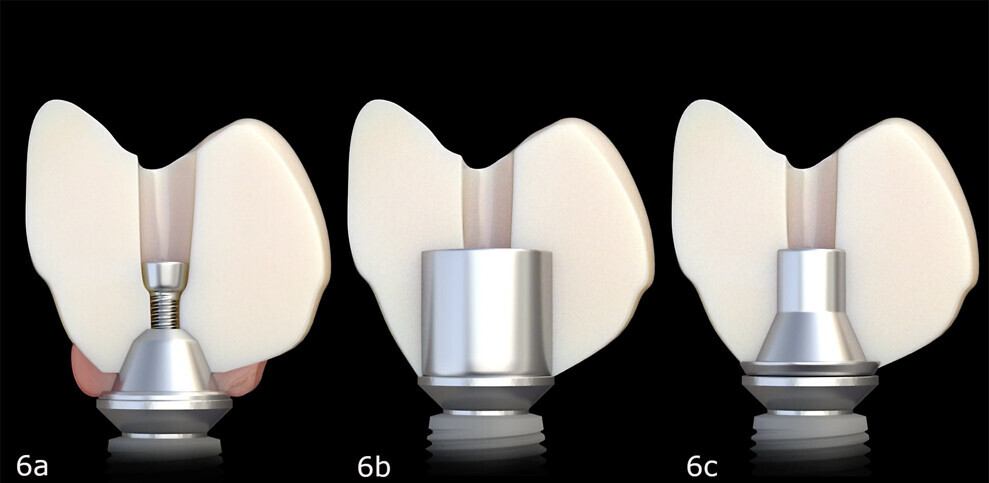

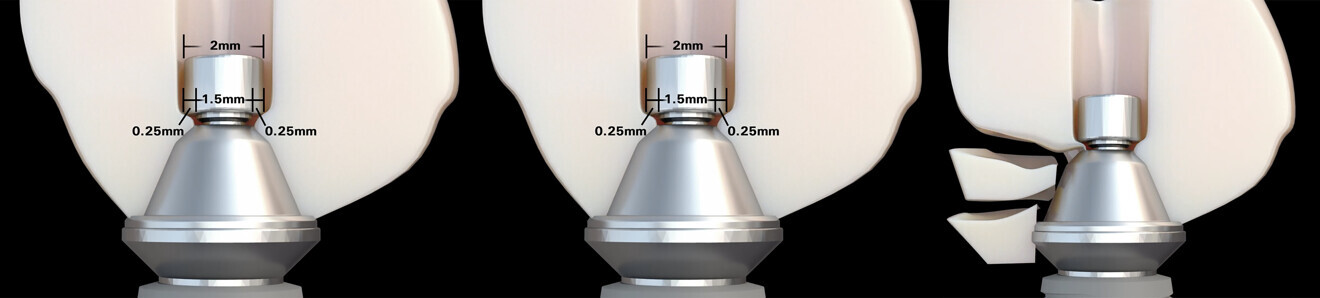

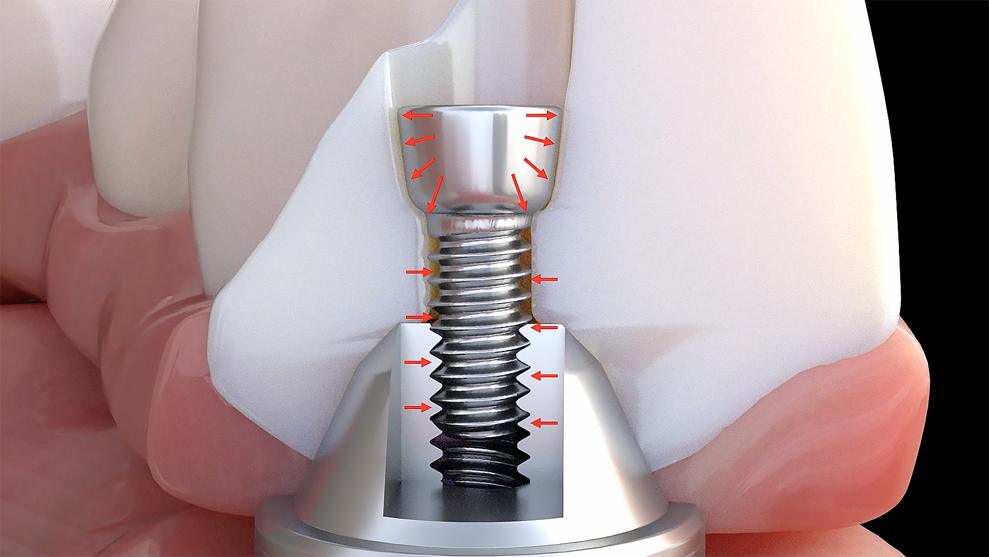

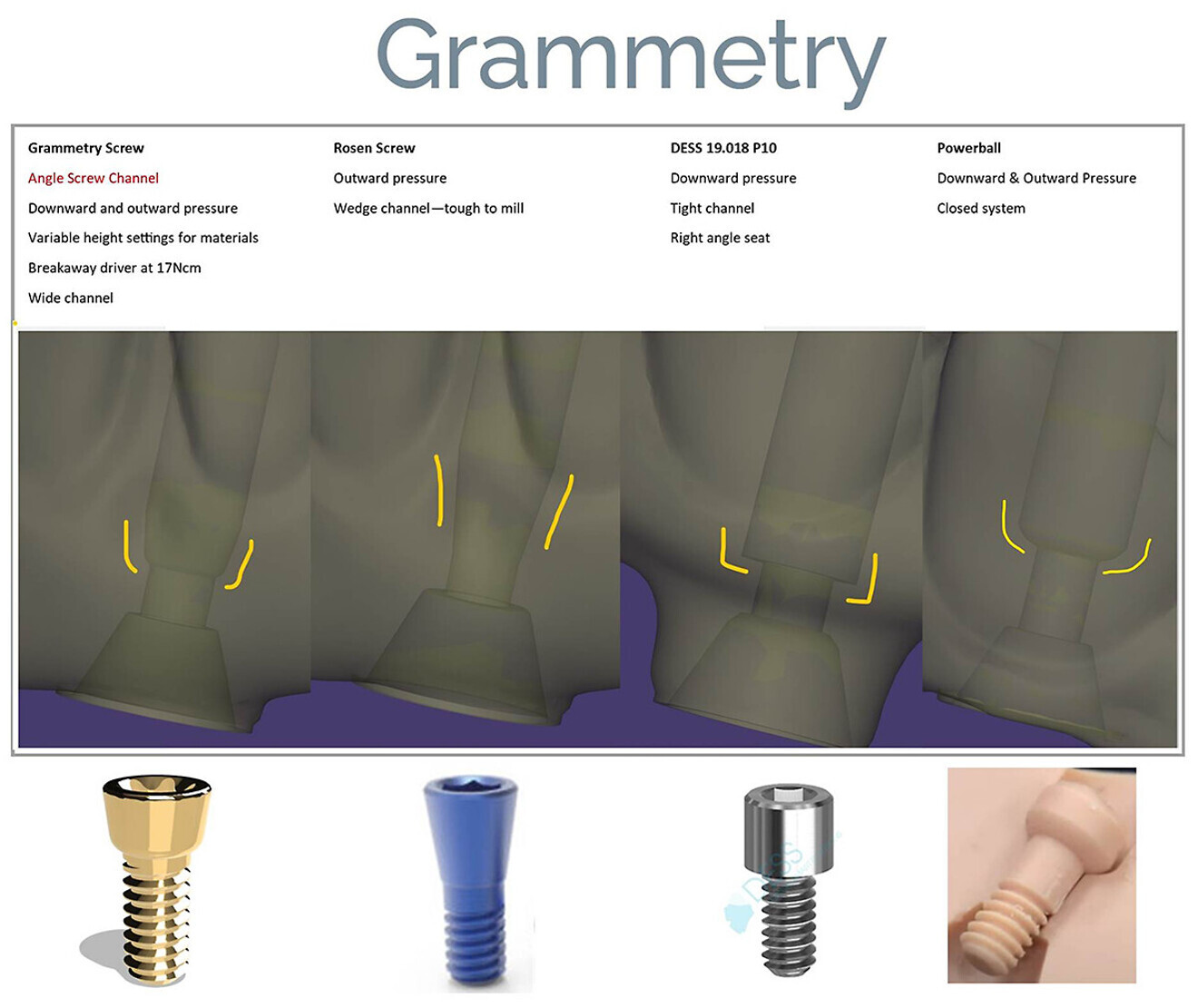

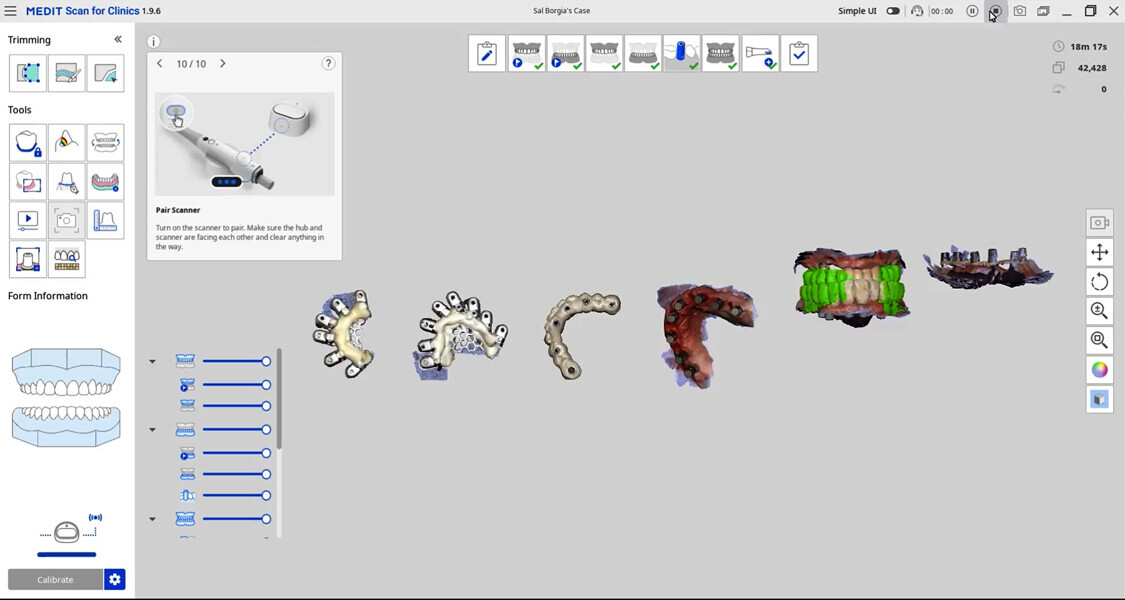

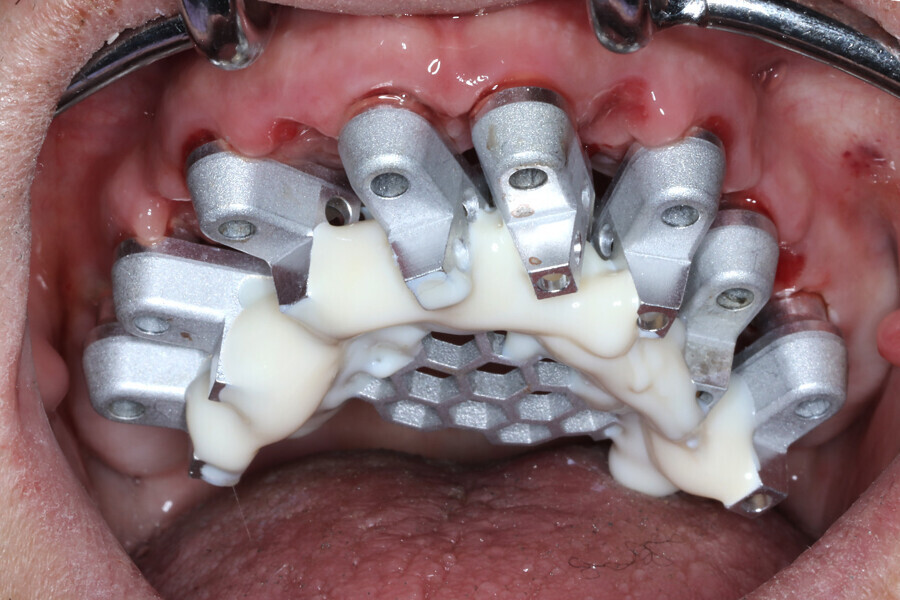

The present case described digital and analogue protocols for capturing soft-tissue topography as well as the use of iJIG provisional restorations essential to aligning and validating the intra-oral position of restorations, as well as the use of Grammetry and photogrammetry. Voids can be shown with accuracy and adjusted to be filled in using design software. With incorporation of a 2D profile photograph or, better yet, a 3D facial scan, tooth position, size and shape can be easily managed for an improved try-in or final restoration.

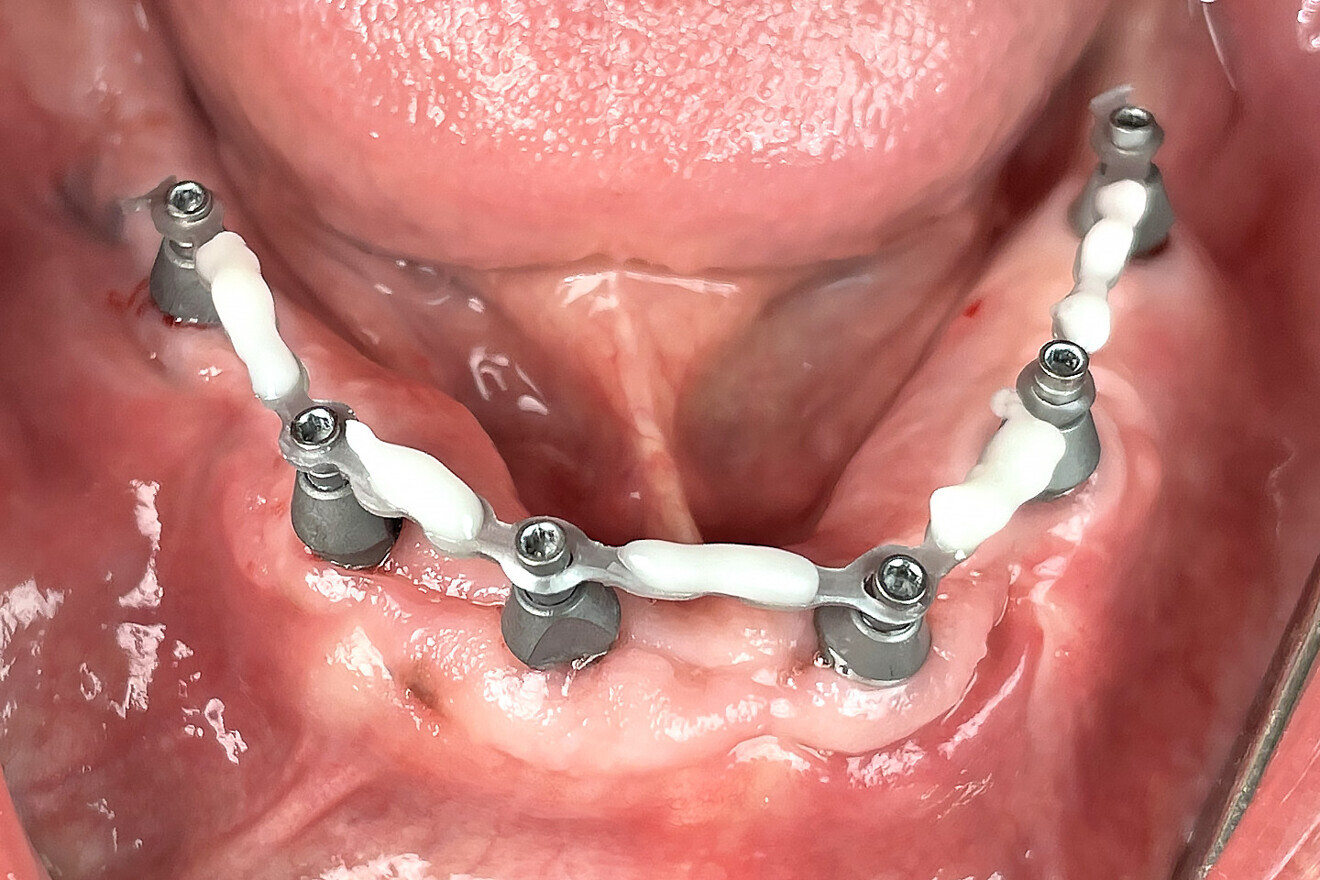

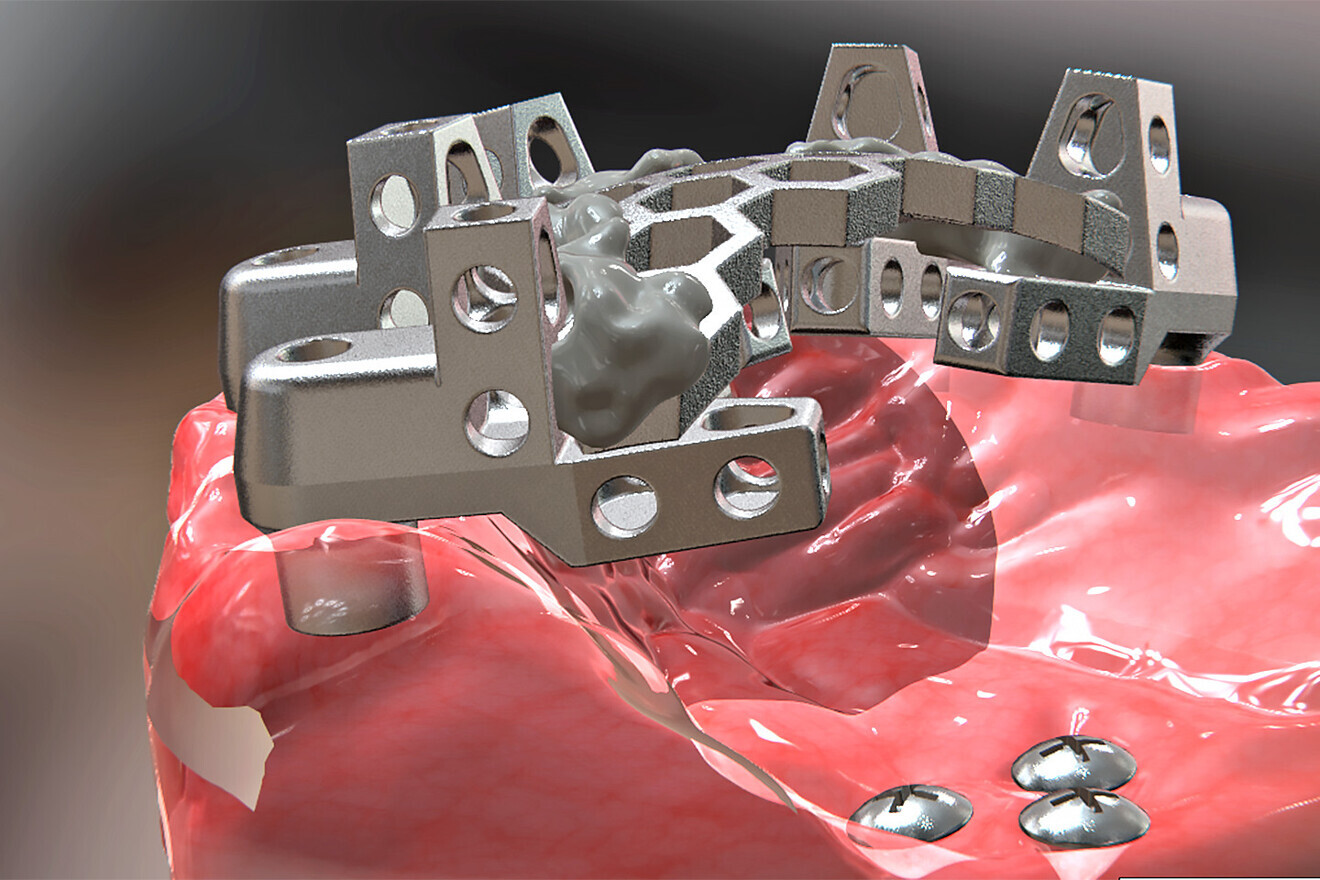

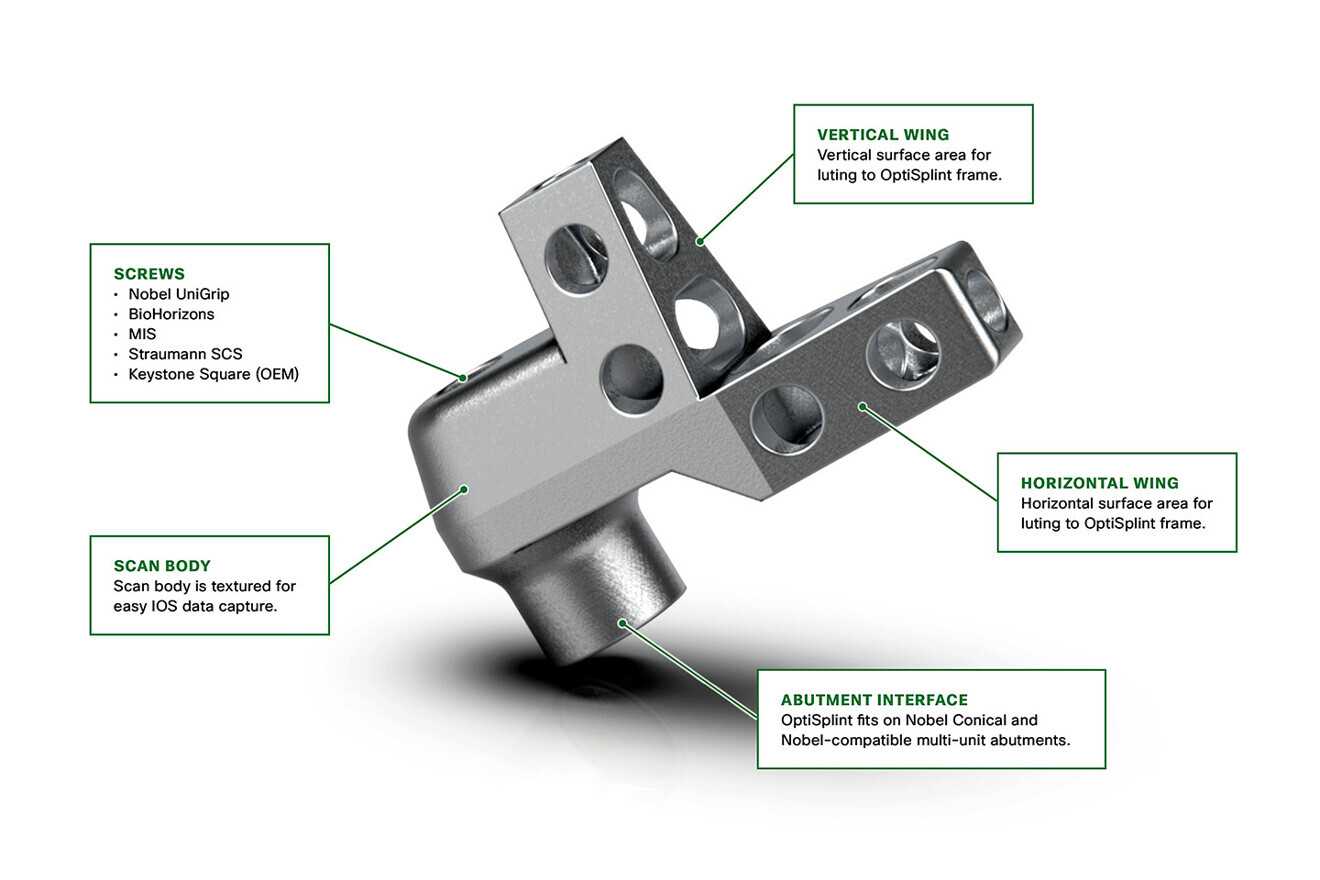

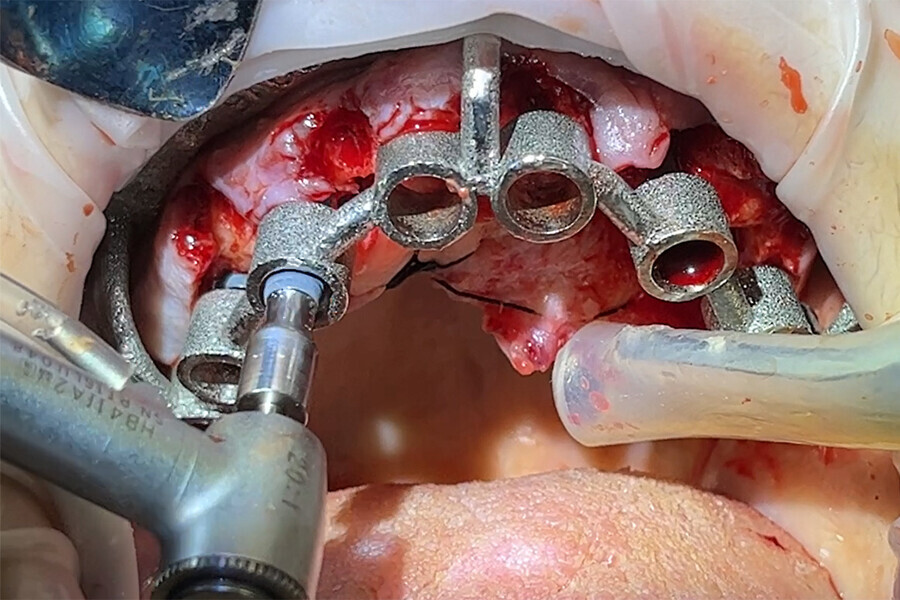

In this case, three methods were utilised to capture data to provide a basis of comparison. The first, photogrammetry, has been acknowledged as the gold standard for implant position accuracy. The second, Grammetry, utilised the new OptiSplint analogue luting protocols. The third, digital capture, utilised the Grammetry OptiSplint, in which the intra-oral scanner and extra-oral desktop captures were analysed and compared. The extra-oral desktop capture of the Grammetry OptiSplint was almost identical to the photogrammetry capture when both data sets were superimposed. The extra-oral desktop capture of the Grammetry splint yielded marginally better results than the intra-oral scan captured extra-orally. Although the results may be slightly less accurate due to the human error associated with intra-oral scanners, they were more than acceptable, as CAD/CAM unit tolerances prevent milling beyond the results obtained. An added benefit of using the Grammetry process is the possibility of producing a physical model, allowing for an analogue try-in for producing both printed try-in and final milled restorations.

In summary, there are various existing digital workflows which can be successfully utilised to achieve consistent and accurate results for full-arch implant-supported restorations. Currently, owing to supply chain shortages and limitations, photogrammetry devices are on back order and in short supply. Grammetry protocol components are both available and less expensive. For the purposes of this case presentation, it was found that the analogue–digital protocol of Grammetry can be used as an effective, affordable and equally accurate alternative to photogrammetry. In combination with the necessary records, Grammetry can provide a fully digital capture of implant positions while providing analogue models if desired for articulation and restoration fabrication. Capturing data either on the day of surgery or later on can greatly improve dental laboratory communication and reduce final prosthesis production time while supporting a high level of accuracy, enhancing the overall clinical and patient experience. Future research on the protocols and materials utilised for this case presentation is recommended, as the search for the most economical and accurate digital workflows continues to evolve.

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

International / International

International / International

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register